Excellent CO2 balance for rPET made by PET Recycling Team

Recycled PET made by PET Recycling Team GmbH (PRT) produces 79% less CO2 emissions than virgin PET. This value could be approved by a study published by “denkstatt GmbH”.

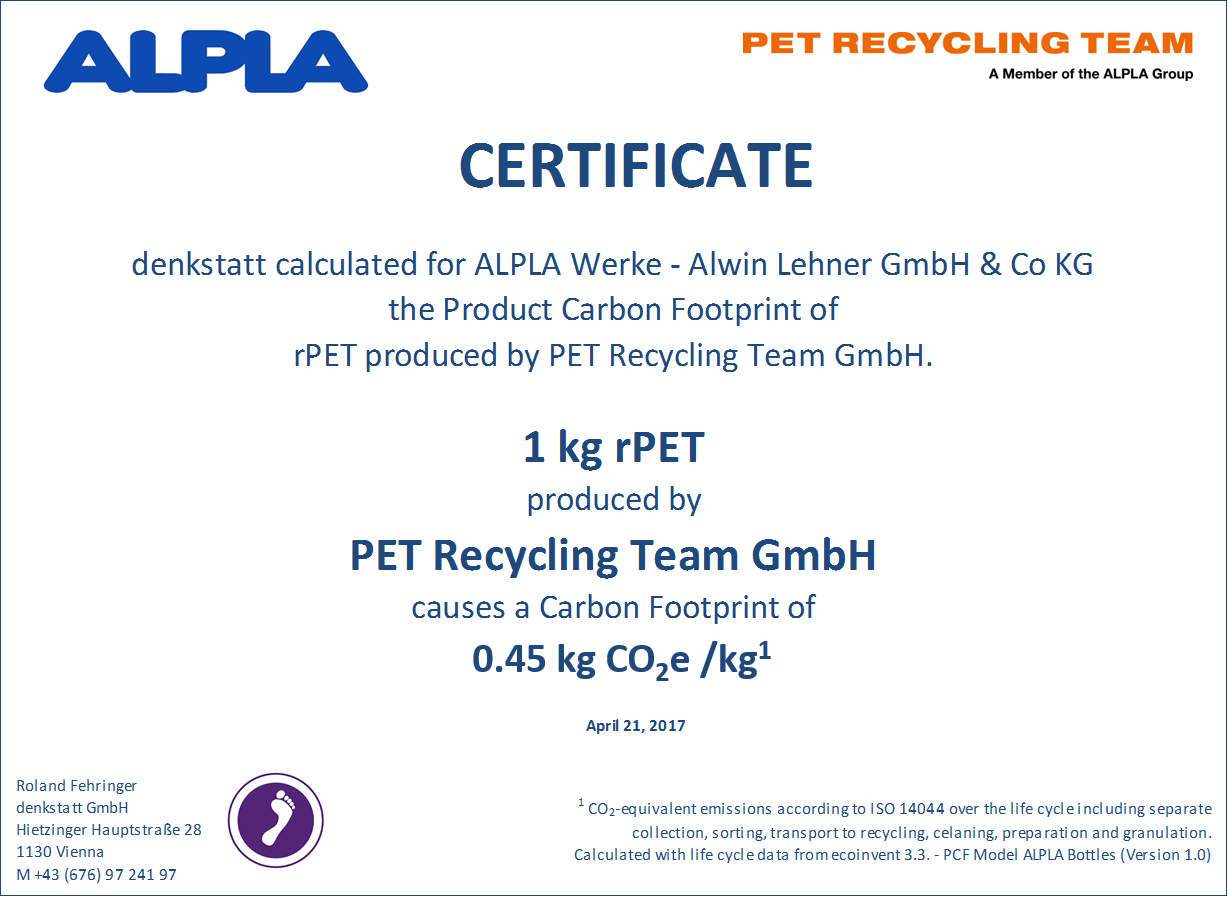

ALPLA believes in recycling even though economic conditions, such as low oil prices, do not favor the recycling of plastics. In order to underline the meaning of reusing plastic, ALPLA contracted Roland Fehringer of denkstatt GmbH to calculate the carbon footprint of rPET (see factbox).

The study results exceed previous assumptions: the rPET produced by the PET Recycling Team GmbH in Wöllersdorf has a carbon footprint of 0,45 kg CO2-equivalent per kilogram of rPET. So called virgin PET (new material) produces 2,15 kg CO2-equivalent per kilogram PET. rPET therefore reduces greenhouse gas emissions by 1,7 kg CO2-equivalent or by 79 percent when compared to virgin PET. With the savings produced by only 1 kg rPET it would be possible to light a 13 Watt lightbulb for 20 days, using the Austrian energy mix.

The carbon footprint was calculated according to ISO 14044 and takes into account the collection and sorting out of used PET bottles, their transportation to the recycling plant in Wöllersdorf, and washing, processing and granulating the material. The analysis is based on the mass and energy balances (electricity and gas consumption) 2016 of the recycling plant Wöllersdorf in Austria.

- What is the carbon footprint?

-

The carbon footprint shows how much greenhouse gas emissions, such as CO2, methane and nitrous oxide, are emitted during the whole life cycle of a product or a service. It is calculated for a determined functional unit – in this case for one kilogram rPET, produced in 2016 in the recycling plant of the PET Recycling Team GmbH (part of the ALPLA group) in Wöllersdorf. Further general information regarding the calculation are available at www.carbonfootprint.at.